Twin Roller Wear Tester Application used to study tribological properties of metal to metal to abrasive media composites and polymers etc. under dry or lubricated condition and elevated temperatures upto 500°C. The test tracks can be linear - unidirectional and reciprocatory circular spiral or as user defined Motion is through 3 axes servo controlled system interfaced with the PC. On line data acquisition of wear, frictional force, coefficient of friction, temperatures and vibration is measured both in dry and lubricated conditions.

Infrared Temperature Sensor, Vibration Sensor, LVDT and Strain gauge sensor.

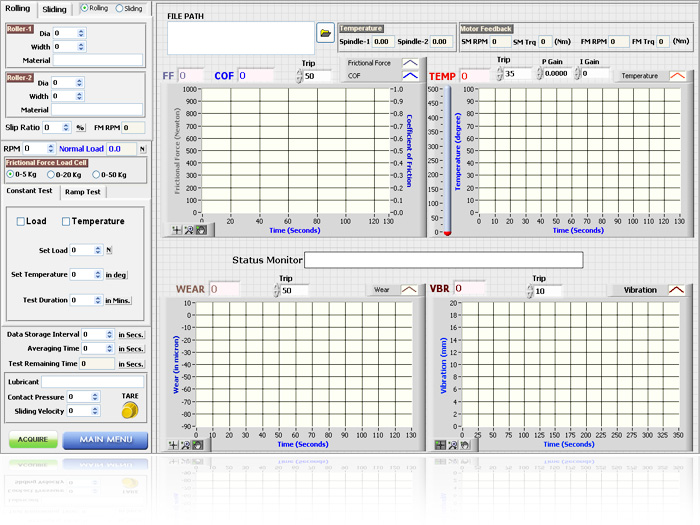

Software: LabVIEW

There are mainly two modes of test namely Manual and Auto Test. In auto test, there are two test conditions as Constant test and Ramp test. The test sequence is controlled by a set of parameters like RPM, Slip Ratio of a spindle, set load, data acquisition rate, test duration, no. of cycles.

The test parameters differs based on test condition. In Ramp test, parameters includes initial load, set load, ramp time and hold time.

Data is acquired through NI DAQ card from different sensors like Strain Guage, Temperate Sensor and Vibration Sensor. Online graph is plotted individually to display Frictional Force, Temperature, displacement, Coefficient of Friction and Vibration. Data is stored into an excel file for further analysis and comparing between tests.

The application software includes option to set the calibration values for various sensors. Administrator and user level security is provided to login to the application.