Softapps has capabilities to provide complete front end engineering solutions utlizing world's leading software tools. We have the expertise and systems to provide a superior service at very cost effective price. Our service is modular & according to customer needs. Our service is based upon a fast turnaround of 24 hours or less, and in some cases overnight. We offer free trial jobs as a means of determining your specification and needs. The first job is returned within 1 to 3 days. After this we will work on a job basis or on a long term contract, the latter reduces the costs and provides dedicated engineers.

Advantages

- Reduce the costs associated with process which will directly impact profitability.

- Will provide much needed redundancy for critical processes.

- Helps in managing the ups & downs in business more effectively.

Quote Data Processing (QDP) activity generally includes the following; however, this is customized to each customer's requirements:

- Download and screen customer supplied electronic data (Gerber files, drawings, etc.).

- Verify that the customer supplied information is complete and the job is well within the pre-set manufacturability limits.

- Prepare and send a clarification note, as per an agreed template, if the information is in-complete or the job is not within the manufacturability limits.

- Complete a quote request form by either remotely accessing the quote system in use, or in a pre-determined format that can be easily or automatically read.

Pre-CAM activity generally includes the following; however, this can be customized to each customer's requirements:

- Read customer supplied electronic data (Gerber files, drawings, etc.) in any recognized format.

- Align all layers.

- Re-name layers as per pre-determined naming conventions.

- Assign layer attributes.

- Drawn to flash pad conversions.

- Contour drawn or filled areas.

- Assign feature attributes.

- Perform any other customer specific operations.

- Prepare any other customer specific reports.

- Output data in ODB ++, or any other customer specific format.

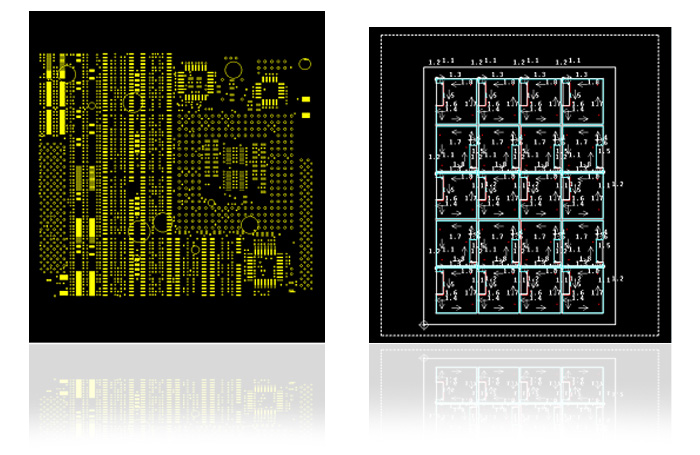

Front End Engineering activity generally includes the following; however, this can be tailored to each customer's requirements:

- Modify/Generate drill layer, as per customer specific tolerances.

- Etch compensation as per customer specific requirements.

- Perform DRC as per customer specific parameters.

- Repair DRC errors as per customer specific guidelines.

- Slivers, acid traps and pin hole elimination.

- Repair/generate solder-mask layer.

- Perform silk screen (Legend) clippings.

- Generate any other job specific layers and drawings (peelable, carbon, gold plating, via plugging, mechanical drawings, drill drawing, etc.).

- Create route profile.

- Add customer and job specific logos, markings, date code, etc.

- Palletize as per job requirements (create array).

- Panelize as per customer specific panel frames, and add any other feature as required.

- Output and send completed files after thorough validation.

Scripting activity generally includes the following; however, this can be tailored to each customer's requirements:

- Modify or porting pre-written customer scripts to our environment.

- Scripts for customers for automation or as per customer specific requirements.

- Developing In house scripts.

- Scripting Tools – Perl, Python & TCL/TK.